So, Ensure that you question the shopper the spots wherever they expect tools trustworthiness. The shopper needs to be apparent regarding their requirements. They must condition the confirmations they need from a factory acceptance test.

Make a listing of the kind of failures you’ve knowledgeable or could possibly working experience in output, as well as predicted results. Use this checklist to totally evaluate equipment efficiency in the Extra fat. Devices Use a pure backup curve that is all about early failures.

Dependant on the results on the Unwanted fat, equally parties can produce a punch list of further items that should be dealt with before shipment.

Like a rule in all industrial configurations, the safety of machinery operators should keep on being a precedence and the usage of Body fat gear will provide the necessary protection specifications.

The Fats is normally executed in the producer function store. The company checks that the security instrumented program is effective as intended and In keeping with the necessities stated in the security procedure operates as intended and In accordance with the requirements the protection needs specification, NRN. Throughout the Body fat the company checks:

This proactive tactic don't just accelerates the testing process but additionally instils self confidence from the products’s trustworthiness and performance, demonstrating the manufacturer’s determination to offering a high-quality item that meets purchaser anticipations.

The desired competence for associated test personnel is explained during the setting up. It is suggested that personnel with experience suitable for the supposed course of action application and basic safety instrumented process promotions Along with the Fats scheduling.

If the pump activates it implies that everything will work good for this enter and also the logic. Should the oil pump isn't going to activate, I must take a look at the wiring or my PLC factory acceptance test example logic.

Complete a review with the devices from a safety point of view. Hunt for badly guarded parts and pinch details. Run your hands throughout the device (very carefully), searching for sharp edges and burrs. Test to be sure all Restrict switches and emergency stops are completely functional, robust, and correctly put. Test for flaws in all built in safety factors.

Therefore, you'll need to commit numerous hrs for the shopper’s web-site solving concerns you might have easily taken care of in advance of shipping and delivery the user interface. So, because the title implies, a Unwanted fat is accomplished in the factory.

This offers operators the opportunity to make certain that the gear is running as supposed and gives them the peace of mind that their leading-quality tools will run properly within the get-go. Factory acceptance testing may even offer guides to right set up, enabling operators to enhance installation time.

Primarily concluded by installing HVAC elements/devices right into a goal-designed chamber so that ambient situations is often managed and simulation performed.

Brands can customise testing established-ups and configurations as needed to simulate serious-entire world operating disorders and assess the products’s effectiveness below numerous eventualities. With their competent staff on website, we could determine and diagnose challenges additional efficiently in the testing method and attain useful insights and proposals for optimising the product’s functionality and addressing any deficiencies uncovered during testing.

The objective of the SAT will be to affirm the machine runs your products towards your requirements in its running surroundings. Understanding the difference between a FAT and read more SAT could help you save as well as the supplier time, dollars, and aggravation.

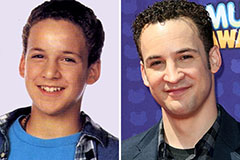

Ben Savage Then & Now!

Ben Savage Then & Now! Mason Gamble Then & Now!

Mason Gamble Then & Now! Barry Watson Then & Now!

Barry Watson Then & Now! Tiffany Trump Then & Now!

Tiffany Trump Then & Now! Terry Farrell Then & Now!

Terry Farrell Then & Now!